Worlds Best Material Handling System

Material Handling System

World Best Material Handling System

We Offer A Great Variety Of Products

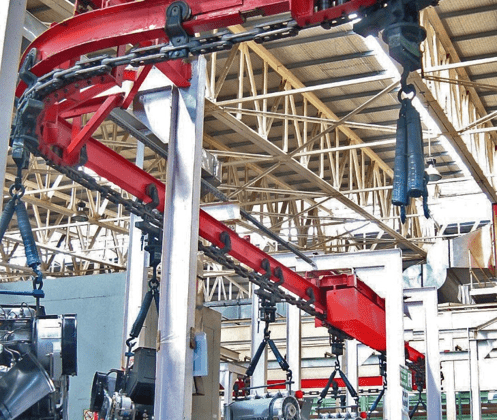

- Efficient Material Handling: Moves heavy or bulky items along a production line using suspended overhead tracks.

- Space-Saving Design: Frees up floor space by utilizing overhead pathways, ideal for crowded or limited areas.

- High Load Capacity: Supports the transport of large, heavy loads, improving productivity in industrial environments.

- Customizable Pathways: Offers flexible routing options with adjustable angles, curves, and lengths to suit specific workflows.

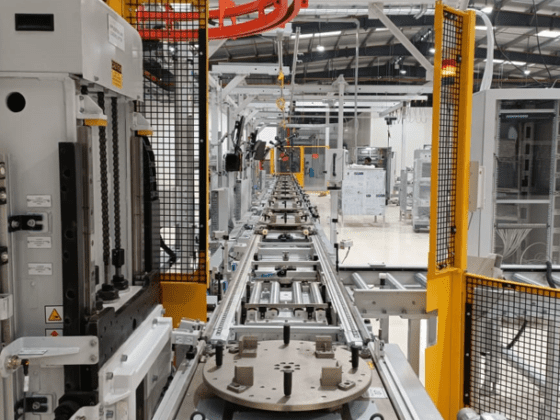

- Automated Transport: Uses powered rollers to move materials efficiently along the conveyor system, reducing manual labor.

- Versatile Handling: Ideal for transporting boxes, pallets, or irregularly shaped items in warehouses and production lines.

- Adjustable Speed: Features variable speed settings for controlled material movement and optimized workflow.

- Durable & Low Maintenance: Built with robust materials for long-lasting performance, requiring minimal maintenance.

- Intermittent Movement: Operates in a “stop-and-go” fashion, halting and starting as needed to match production cycles or sorting tasks.

- Improved Efficiency: Helps manage flow by stopping at specific points for loading, unloading, or processing items in stages.

- Versatile Application: Ideal for assembly lines, packaging, and order picking, where timing and sequencing are critical.

- Controlled Operation: Often integrated with sensors or controls for precise stopping and starting, ensuring smooth workflow management.

- Hands-Free Operation: Automatically moves materials or products along the conveyor system without manual intervention, improving efficiency.

- Smart Controls: Features sensors, motors, and automated controls to adjust speed, direction, and timing based on workflow needs.

- Increased Productivity: Reduces labor costs and minimizes human error by automating material handling in manufacturing or distribution processes.

- Flexible Design: Can be customized for various environments, including curved paths, inclines, and integration with other automated systems.

- Fast Material Movement: Designed to transport heavy or bulky items at high speeds, increasing throughput in industrial settings.

- Durable Construction: Built with heavy-duty chains and components to handle demanding environments and high-load capacities.

- Smooth Operation: Provides continuous, reliable motion for efficient material handling with minimal interruptions.

- Versatile Application: Ideal for bulk material handling, packaging, and assembly lines in industries such as automotive, manufacturing, and logistics.

1. Enclosed Track Design: Features a closed-loop chain system, protecting the conveyor from debris and external contaminants for smooth operation.

2. Heavy-Duty Performance: Built to handle heavy loads, ensuring reliable transport of goods in tough industrial environments.

3. Space-Saving: The compact, overhead design saves valuable floor space, ideal for environments with limited room or high-density layouts.

4. Durability & Low Maintenance: Robust construction minimizes wear and tear, reducing the need for frequent maintenance and enhancing system longevity.

- Manual Operation: Relies on human effort to move trolleys along an overhead track, offering flexibility in material handling.

- Space-Saving Design: Uses overhead tracks to free up valuable floor space, ideal for tight or congested work areas.

- Customizable Pathways: The system can be configured with straight, curved, or inclined tracks to fit specific production line needs.

- Durable & Simple: Constructed with sturdy materials for long-lasting use, with minimal maintenance required for smooth operation.

1. Continuous Movement: Utilizes flight bars (horizontal bars) to transport products securely along the conveyor, ensuring smooth, steady movement.

2. Heavy Load Handling: Ideal for transporting bulky or heavy items, such as pallets or large containers, in industries like automotive or manufacturing.

3. Durable Construction: Built with robust materials to withstand harsh environments and heavy-duty use with minimal maintenance.

4. Versatile Design: Can be configured for straight, inclined, or curved paths to fit various production line layouts and workflows.

1. Inverted Design: Operates with a chain running along the floor, supporting load-bearing pallets or carriers from underneath, freeing up overhead space.

2. Heavy Load Capacity: Designed to transport large, heavy items, such as automotive parts or bulky goods, with high efficiency and stability.

3. Durable & Robust: Built with high-strength materials to withstand demanding industrial environments and reduce wear and tear.

4. Flexible Layout: Can be customized with straight, curved, or inclined tracks to meet specific production line or material handling needs.

Applications

Automotive

Aviation

Agriculture Equipment

Heavy Duty Truck

Manufacturing & Industrial

Marine &

Yacht

Construction

Wood Finishing

Infrastructure

Get an Easy Quotation For Your Industry

- +91 9890013871

- sales@techexpertindia.com

- TECHExpert House, 78, Off NDA Road, Pandurang Industrial Area, Shivane, Pune, Maharashtra 411023