Ionisation

Many plastics used today attract particles floating in the air due to electrostatic surface charges. These particles affect the painting quality, o.k. rate, rework rate, and reject and should therefore be professionally removed before coating.

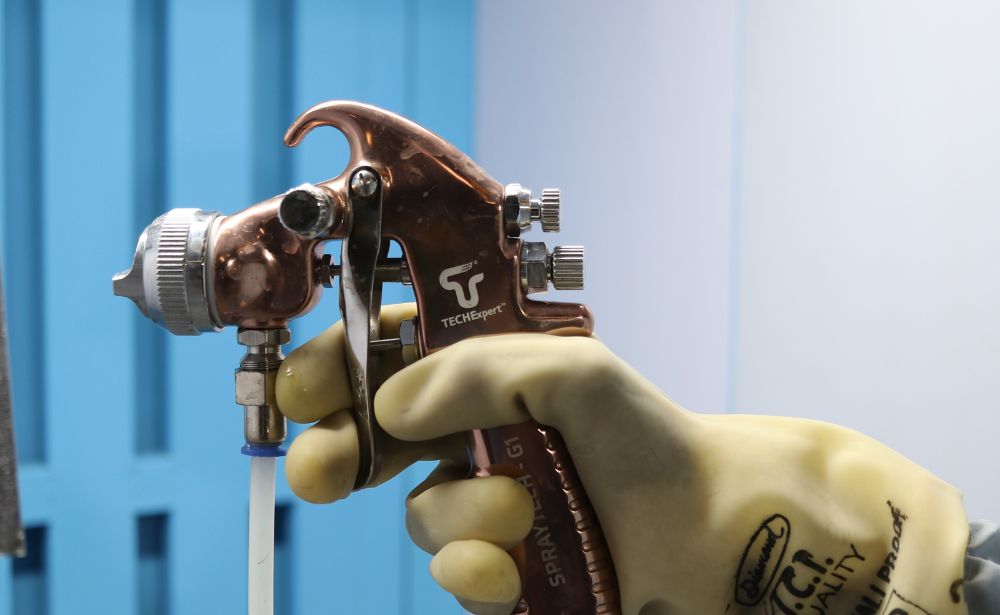

Since the removal of these particles can hardly be achieved with conventional methods, TechExpert uses ionization devices for cleaning – if it is reasonable and necessary. The ionizing units neutralize the surface and thus improve the quality of the coated end product. In this process, the workpieces are usually wetted from above and/or from the side.

TechExpert has developed a circulating air process for the ionization zone that does not require expensive compressed air so that enormous savings potential can be achieved concerning process costs.

Features & Benefits

Consistent Quality

Eco-energy

Easy Maintenance

On-Time Delivery

Energy Saving

Efficiency

Applications

Precision components

Read more

Automation Industry

Read more

White goods

Read more

Steel Furniture

Read more

Get In Touch

Call us or send an email and we’ll get in touch shortly, we endeavor to answer all inquiries.