Down Draft Cross Flow

- Home

- Down Draft Cross Flow

Down Draft Cross Flow

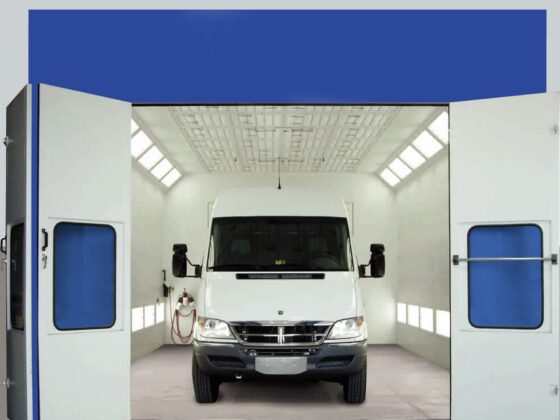

A Down Draft Cross Flow Paint Booth is an advanced enclosure designed for the efficient application of paint and coatings, utilizing a unique airflow system that combines down draft and cross flow principles. In this system, air is drawn down from the ceiling and exhausted through side filters, promoting excellent ventilation and ensuring a clean painting environment. This type of booth is particularly effective for achieving high-quality finishes while minimizing contamination and defects. It is commonly used in automotive, aerospace, and industrial manufacturing applications.

The Down Draft Cross Flow Paint Booth features an innovative design that incorporates a dual airflow approach. Fresh air is introduced from the ceiling, where it flows downwards, while the exhaust is pulled through the sides. This configuration allows for efficient removal of overspray and particulates, ensuring a clean and controlled environment for paint application. The booth is typically equipped with advanced filtration systems to enhance air quality and maintain optimal conditions for coating processes.

In the establishing year 1998, TECHExpert Engineering Pvt Ltd embarked on a journey in the manufacturing industry for Surface Coating Plants and Equipment. In less than two decades, we have become the leading genus in Designing, Manufacturing, Supplying and Exporting a wide range of Pre-Treatment Plant, Powder Coating Plant, Paint Booth Manufacturer, Industrial Oven Manufacturer, Curing Oven Manufacturer, Material Handling Equipment, Conveyor Suppliers, Industrial Ducting Suppliers, and Shot Blasting System.

Benefits of Down Draft Cross Flow

- The down draft airflow effectively removes overspray and airborne contaminants from the painting area, leading to a cleaner environment and higher-quality finishes.

- Proper ventilation and air filtration help to manage hazardous fumes and VOC emissions, protecting operators and ensuring compliance with environmental and safety regulations.

- The dual airflow system promotes faster drying times for painted surfaces, increasing throughput and productivity in manufacturing processes.

Use of Down Draft Cross Flow

- Used for painting vehicle bodies and components, ensuring high-quality finishes while efficiently managing overspray and maintaining a clean working environment.

- Utilized for coating machinery, equipment, and industrial parts, providing a controlled environment that enhances coating quality and durability.

- Used for coating metal components and structures, enhancing corrosion resistance and overall durability while ensuring a high-quality paint application process.

TECHExpert Engineering Pvt Ltd, we have grown into offering end-to-end solutions in the field of Surface Coatings, beginning with Consultancy, Designing, Engineering, and Commissioning of tailor-made systems for powder coating, liquid painting, and Metal pre-treatment, on a turnkey basis, for a wide range of utilization necessities of finish coating for industrial and customer products.

Further, to attain maximum satisfaction of clients, we provide after sales service with the help of our trained and experienced engineers. Our vast industry experience and in-depth knowledge have helped us in acquiring huge base of clients not only in India but also in overseas countries like UAE, Bahrain, Qatar, Quwait, Africa, and Oman.